绞车的制作教程

电子说

描述

步骤1:零件

要复制此内容,您需要收集一些部分。我开始为这个项目采购电机,并且能够在eBay上找到两个Jazzy牌轮椅电机。我用于这个项目的其他部分是:

()2 Arduino Uno板

(2)nRF24L01收发器,带背包

(1)SyRen10电机驱动器

(1)24伏电源

(1)5伏电源

10k欧姆电阻器

瞬时按钮

3d印刷材料

制造材料 - 用于底盘,螺钉,螺栓等的钢材

第2步:制造

我做的第一步是测试电机并确保它能正常工作。我测试了接线,并找出了哪些电线连接到电磁制动器以及哪些电线连接到电机。通过向制动器运行24伏电压,它们将释放并允许电动机自由转动。

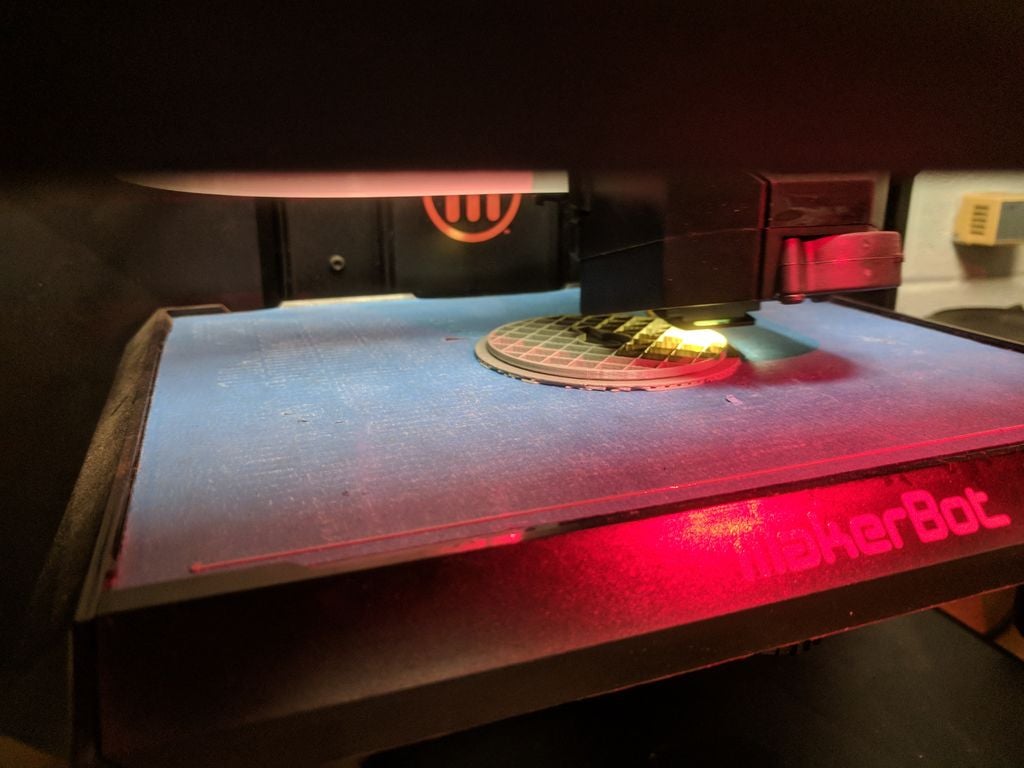

我开始为3英寸电缆卷筒打印三维部件,电缆卷筒位于电机轴上。我用钢板切割了两个5英寸的圆盘,并在钻孔后将它们安装在两侧。 3d打印的鼓。我焊接了一个底盘,用一个1英寸的箱形钢管将电机拧紧。装配好电缆卷筒并将绞盘安装到底盘后,我准备从硬件上移开。

第3步:软件

编码经过多次测试迭代,找出最佳方法无线控制。一个版本有一个旋钮控制速度和方向与GO按钮。这非常方便动态调整,但不可重复。

代码的最终版本设计可编程根据命令执行的提示。对于这个版本,只有两个提示可供选择,这些提示在Arduino软件中编程。那些在他们的工具包中有超过3个按钮的人可以轻松扩展功能。选择提示加载将信息输入当前提示,然后按住GO按钮命令电机移动。释放按钮自动y停止电机,作为一种死人开关。最后,作为一种紧急停止,通过翻转电源板上的开关或从墙上拔下电源来切断电机电源,将使制动器停止并停止电机。

我的发射器代码嵌入在下面。

/* Transmitter Code

* Code to store a cue and transmit it with a RF24L01+ to a receiver

* Credit to Mark Hughes for sharing his remote control project that

* helped me understand and debug my nRF24L01 setup

*

* This is the code for the transmitter portion for my winch project.

* It consists of 2 buttons, each with cue information, and a third button

* which is the “GO” button. Pressing and holding the button transmits to

* the receiver the information for the motor controller.

*

* Hook Up from nRF24L01

* Gnd to GND

* VCC to VCC

* CE to Digital 9

* CSN to Digital 10

* SCK to Digital 13

* MOSI to Digital 11

* MISO to Digital 12

* IRQ to Digital 8

*/

#include SPI.h

#include RF24.h

// Radio Configuration

RF24 radio(9,10);

byte addresses[][6] = {“1Node”,“2Node”};

bool radioNumber=1;

bool role = 1; //Control transmit 1/receive 0

//hardware attachments

const int GoButton = 4; //hold button to run loaded cue

const int Cue1 = 3; //press button to load cue

const int Cue2 = 2; //press button to load cue

const int ledPin = LED_BUILTIN; //LED flashes for debug purposes

//variables

int GoButtonState = 0;

int Cue1State = 0;

int Cue2State = 0;

int MotorSpeed = 0;

int STOP = 0; //for deadman switch. Constant broadcast a 0 speed to winch for safety

void setup() {

// put your setup code here, to run once:

pinMode (ledPin, OUTPUT);

pinMode (GoButton, INPUT);

pinMode (Cue1, INPUT);

pinMode (Cue2, INPUT);

Serial.begin(9600); // Get ready to send data back for debugging purposes

radio.begin(); // Get the transmitter ready

radio.setPALevel(RF24_PA_LOW); // Set the power to low

radio.openWritingPipe(addresses[1]); // Where we send data out

radio.openReadingPipe(1,addresses[0]);// Where we receive data back

}

void loop() {

// put your main code here, to run repeatedly:

GoButtonState = digitalRead(GoButton);

Cue1State = digitalRead(Cue1);

Cue2State = digitalRead(Cue2);

// Serial.print(ForeAft_Output);

radio.stopListening(); // Stop listening and begin transmitting

delay(50); // make delay longer for debugging

while (digitalRead(GoButton) == HIGH) {

SendMotorSignal(); //subroutine for broadcast

}

if (Cue1State == HIGH) {

MotorSpeed = -127; //speed for Cue1. Input can be from -127 to 127

digitalWrite(ledPin,HIGH); //LED flashing is helpful for debug

delay(100);

digitalWrite(ledPin, LOW);

delay(200);

}

if (Cue2State == HIGH) {

MotorSpeed = 127; //speed for Cue2. Input can be from -127 to 127

digitalWrite(ledPin, HIGH); //LED flashing is helpful for debug

delay(200);

digitalWrite(ledPin, LOW);

delay(100);

}

else {

digitalWrite(ledPin, LOW);

radio.stopListening(); // Stop listening and begin transmitting

delay(50); // make delay longer for debugging

if(radio.write(&STOP, sizeof(STOP)),Serial.println(“sent STOP”)); //Deadman switch function. Sends value of 0

radio.startListening();

//delay(50); //make delay longer for debugging

}

}

//subroutine for sending signal to motor

void SendMotorSignal() {

radio.stopListening();

delay(50); //make delay longer for debugging

if(radio.write(&MotorSpeed, sizeof(MotorSpeed)), Serial.println(“sent MotorSpeed”),(MotorSpeed));

digitalWrite(ledPin,HIGH); //LED helpful for debug

delay(100);

digitalWrite(ledPin, LOW);

delay(50);

}

对于接收器。

/* Receiver Code

* Code to receive data from RF24L01+ and use it to control a motor

* Thanks to Mark Hughes for sharing his remote control project that was

* incredibly valuable to me for learning how to make the radio library function.

*

* This is the code for the receiver portion for my winch project. It listens

* for the motor speed information to be transmitted, then sends it to the SyRen

* motor controller using a simplified serial packet.

*

* The receiver is using Software Serial to have the communication line to the SyRen

* on Pin 3, primarily so that the Arduino can be plugged into the computer

* during development.

*

* Hook Up from nRF24L01

* Gnd to GND

* VCC to VCC

* CE to Digital 9

* CSN to Digital 10

* SCK to Digital 13

* MOSI to Digital 11

* MISO to Digital 12

* IRQ to Digital 8

* */

#include SoftwareSerial.h //for serial communication on a designated pin

#include SyRenSimplified.h //library for SyRen

#include SPI.h

#include RF24.h

//SyRen Config

SoftwareSerial SWSerial(NOT_A_PIN, 3); // RX on no pin (unused), TX on pin 3 (to S1)。

SyRenSimplified SR(SWSerial); // Use SWSerial as the serial port.

//Radio Configuration

bool radioNumber=0;

RF24 radio(9,10);

byte addresses[][6] = {“1Node”,“2Node”};

bool role = 0; //Control transmit/receive

// Create variables to control servo value

unsigned int MotorSpeed; // Expected range -127 to 127

void setup() {

Serial.begin(9600); // Get ready to send data back for debugging purposes

SWSerial.begin(9600); // for communication to SyRen

radio.begin(); // Initialize radio

radio.setPALevel(RF24_PA_LOW); // Set the power output to low

radio.openWritingPipe(addresses[0]);

radio.openReadingPipe(1,addresses[1]);

radio.startListening();

}

void loop() {

delay(50); //increase for debuggy, decrease to decrease jitter

if(radio.available()){

radio.read(&MotorSpeed,sizeof(MotorSpeed));

}

else {Serial.print(“No radio”);

}

//Serial.print(MotorSpeed); //for debug purposes

//Serial.print(“ ”);

//delay(100);

//delay can be helpful when debugging- can be finetuned, but no delay causes

//glitches to happen in serial monitor. I think there may be conflict

//between SWSerial to the Syren and nRF and USB serial.

SR.motor(MotorSpeed); // Command the motor to move or, where the magic happens

}

这就是编码!

第4步:全面测试

这里有一些视频,我正在测试车间的绞车,以及一些额外的组件图片。

一些想法 -

底盘设计为可以以不同方向安装,并且可以轻松添加C形夹,奶酪架或直接安装在地板或甲板上。通过无线设置,绞车仅需120伏电源即可与其接收器一起工作。变送器只是一个独立的电源,因此也需要一个插座插入。

速度 -

我在这两个方向上的速度都是每秒2英尺左右以最快的速度运行,这是一个非常好的速度,并且与JR Clancy Powerlift系统的速度相匹配。

容量 -

绞盘将保持10磅。它可能会持有更多,但到目前为止,我已经把它增加了10磅。如果不对系统进行破坏性测试,很难猜出故障点是什么。电缆是1/16“英寸的飞机电缆,断裂强度为480磅。我不知道这是否会先失效,或者电机上的轴是否会断裂,或者三维印刷滚筒是否会破碎或撕裂。

然而,对于10-20磅范围内的物体,我认为这种绞盘将完美运作。

扩张 -

我有一些元素我还在努力。有一个编码器和袋鼠板等待麻烦并重新安装在系统上,但我很难让编码器和袋鼠接受对方运行强制调整周期。一旦到位,绞车将具有可编程定位功能。另一个需要的项目是行程顶部的限位开关,以防止有效载荷撞入绞盘。

- 相关推荐

- 绞车

-

副井绞车硬件安全模块与硬件状态显示装置的设计2010-01-12 603

-

如何制作pdf文件,怎么样制作pdf文件2009-05-07 14867

-

微能变频器调试指南--绞车提升机2010-09-20 1226

-

基于XC2C64A芯片的无线录井绞车信号检测电路设计2011-08-21 2821

-

电缆绞车驱动电机的SVM_DTC控制策略2017-01-05 608

-

变频器在调度绞车的实现2017-09-07 496

-

智能绞车的水下实时剖面观测系统2018-02-28 586

-

海洋拖曳绞车液压系统设计与仿真研究2018-03-02 815

-

基于干扰观测器水下绞车控制2018-03-26 1175

-

JD-BP32-90T变频器在调度绞车中的应用介绍2018-12-24 3923

-

如何使用Autodesk Inventor制作绞车模型2019-11-26 2810

-

矿区绞车雷达感应控制人体存在感应雷达保障工作人员安全2021-11-25 664

-

精密导电滑环在电缆绞车上的应用2022-06-07 466

-

零电感水冷电阻器用于船舶,甲板机械的绞车,降低锚和起重机2024-10-08 214

-

绞车驱动器中电源装置的过压保护,制动斩波器-EAK斩波集成电阻器2024-11-23 180

全部0条评论

快来发表一下你的评论吧 !