输配电用的W-Cu触头的无损超声检测过程控制

描述

在与VOGT Ultrasonics GmbH的合作中,设计了一个用于电子束焊接WCu部件和坯料的无损测试的试验台,通过超声波相控阵技术在批量生产条件下进行检测。通过用户的设置和软件分析,可以清晰、容易地识别WCu触头的焊接区质量,提高了工艺稳定性。超声波测试台的一个基本特性是可以根据定义的质量标准立即在线对工件进行分类。该测试的最大挑战是生产中高频次地扫描粉末冶金工艺生产的WCu复合材料组件,并评估焊接区质量。WCu部分通常是焊接到铜合金或钢材上。由于种种原因,超声波束在任何情况下都无法穿过均匀的材料。因此对不均匀的WCu部件进行测量,我们面临的挑战是如何避免由于WCu复合材料的微观结构在密度、重量和均匀性方面存在较大差异而引起的超声反射或偏转。

01

高压电弧触头的工作原理

Figure 1 shows a sketch how an arcing contact component system, consisting of a pin and a so called tulip, works. It is shown that by means of the design of the tulip a minimum spring force has to be achieved to get an optimized and reliable contact to the pin surface. Therefore a maximum of energy transmission can be guaranteed and arcing between the two components can be avoided.

图1是由触指和梅花触头组成的弧触头系统的工作简图。事实证明,通过对梅花触头进行优化设计,可以实现以最小的弹力获得与触指表面最佳和可靠的接触。因此,可以保证最大限度的电能传输,并避免两个触头之间起弧。

图1 电弧触点系统在闭合、导电位置的功能示意图

02

WCu材料

A cross section of a typical WCu microstructure gained by sintering and infiltrating with copper is shown in figure 2. Typical compositions are 60 to 80 wt.-% W and 20 to 40 wt.-% Cu.

图2中显示了通过烧结和熔渗获得的典型WCu微观组织,其组成成分是60~80wt.%的W和20~40wt.-%的Cu。

图2 典型WCu (80/20)微观结构的截面

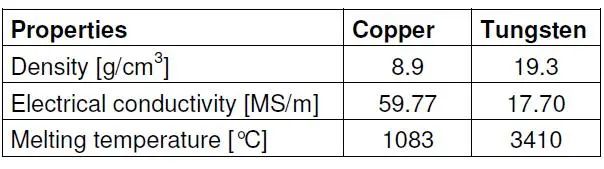

The inhomogeneous microstructure is caused by the very low solubility of W and Cu. The combination of the excellent electrical conductivity of Cu together with the good arcing resistance and high melting temperature as well as high arcing resistance of W, see Table I, results in the usage of contact material for energy transmission up to voltages of 1200kV.

钨和铜的溶解度极低,导致了微观结构的不均匀性。由于Cu具有优良的导电性,加上W具有良好的耐烧蚀性和较高的熔点(见表1),钨铜触头材料适用于特高压的断路器灭弧室中。

03

超声相控阵原理

In general the ultrasonic device transmits electrical pulses to the probe where these pulses are converted to ultrasound waves. After transmitting the waves the probe receives the reflected echos waves as well. All received waves are converted to electrical pulses again and are evaluated by the software. Phased Array probes are composed of several piezoelectric crystals that can transmit/receive independently at different times [5]. To focus or to steer the ultrasonic beam, time delays are applied to the elements to create constructive interference of the wavefronts. Due to this the ultrasonic beam can be steered within a range of angle and/or the energy can be focused at any depth in the test specimen (see Fig. 3).

一般情况下,超声波设备将电脉冲传送到探头,这些脉冲被转换成超声波。在发射超声波后,探头也会收到反射的回波。所有接收到的波再次转换为电脉冲,并由软件进行评估。相控阵探头由多个压电晶体组成,可以在不同时间独立发射/接收[5]。为了聚焦或引导超声波束,对元件施加时间延迟,以产生波束的建设性干扰。因此,超声波波束可以被控制在一定的角度范围内,并且/或者能量可以在测试样品的任何深度聚焦(见图3)。

图3 波束控制和聚焦原理

04

相控阵超声波试验台

The task of the ultrasonic scanning system is to test the weld of the tulip within the production cycle with an offline system. Thereby it detects non connected areas in the weld seam, measures the sizes and classifies the tulips in “good” or “bad” according to given guidelines. The inspection is done by immersion technique.

超声波扫描系统的任务是在检测周期内用离线系统检测梅花触头的焊缝。因此,它检测焊缝中的非连接区域,测量尺寸,并根据给定的准则将梅花触头分为 "好 "或 "坏"。检测是通过浸入式技术完成的。

Depending on the type of tulip there are two possible probe positions to insert the ultrasonic beam perpendicular to the welding. Inspecting the 45 degree weld requires a probe position along the body. The 90 degree weld needs to be inspected from above (see figure 4).

根据梅花触头的类型,超声波束检测位置有两种:检查45度焊缝需要沿着焊缝主体的探头位置,90度焊缝需要从上方检查(见图4)。

图4 典型梅花触头的剖面图(图中标明了超声束方向)

05

相控阵测试示例

Figure 7 (right picture) shows the C-Scan image recorded with a Phased Array system, the result of the conventional immersion inspection is shown in figure 6 as a linear illustration and in figure 7 (left picture) as a round illustration. Comparing both C-Scan images it is to be seen clearly the same results but the way of recording is different. Using Phased Array technique the whole data acquisition and scan imaging lasts no longer than 10 seconds, while the conventional inspection method needs about 2 minutes. Due to the limited capability of the chosen probe in this case the resolution is slightly worse compared to the immersion probe, but it is no effort to get the same resolution like in figure 9 by using another probe.

图7(右图)为相控阵系统记录的C-Scan图像,图6为线性图,图7(左图)为圆形图。比较两个C-Scan图像,可以看到记录方式不同,但结果相同。使用相控阵技术,整个数据采集和扫描成像的时间不超过10秒,而传统的检测方式需要2分钟左右。由于所选探头的能力有限,在这种情况下,分辨率比浸入式探头稍差,但要想得到图6那样的分辨率,可以使用另一个探头。

图7 LS系统记录的圆形图像(左)和相控阵手持装置记录的图像(右)

原文标题:输配电用的W-Cu触头的无损超声检测过程控制

文章出处:【微信公众号:掌知视通讯技术】欢迎添加关注!文章转载请注明出处。

责任编辑:haq

-

无损检测超声波检测原理是什么2024-05-24 4049

-

智能输配电及控制设备包含哪些?2023-04-10 1918

-

输配电是干什么的 输配电及控制设备包括哪些2023-04-06 10241

-

超声波驱动电源在无损检测中的作用2022-01-03 1854

-

超声波驱动电源在无损检测中的应用2021-12-30 1135

-

和伍精密超声无损检测设备2020-08-14 3492

-

基于超声波无损检测技术实现混凝土超声成像检测仪的设计2020-08-13 2244

-

基于超声波无损检测技术实现设计混凝土无损检测仪2019-07-01 5657

-

无损检测技术的介绍与伪彩色技术在超声无损检测中应用2017-10-09 1128

-

超声波无损检测技术分析2017-08-28 1302

-

基于FPGA的超声波无损检测信号处理研究2016-01-04 639

-

2016年美国国际输配电设备和技术展(IEEE )2015-09-15 1659

-

输配电设备手册2012-11-11 2622

-

超声无损检测的发展趋势2010-03-30 808

全部0条评论

快来发表一下你的评论吧 !