用STM32F103C8控制伺服马达的电路连接及代码说明

电子说

描述

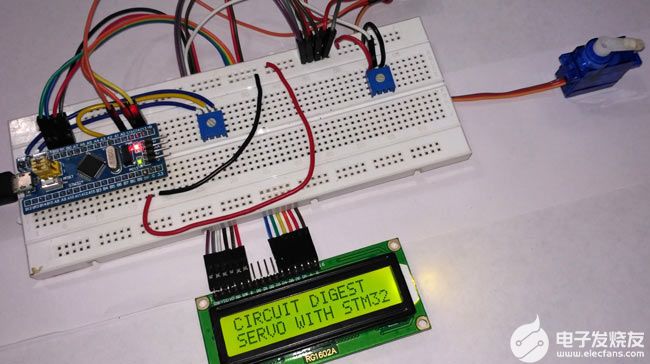

伺服马达(Servo motor)凭准确、小型、高效,易用在机器人领域应用广泛,其高扭矩特性非常适合升降重物。本项目用电位器改变马达转子位置,用STM32F103C8(蓝丸)控制伺服马达,用LCD显示角度值。

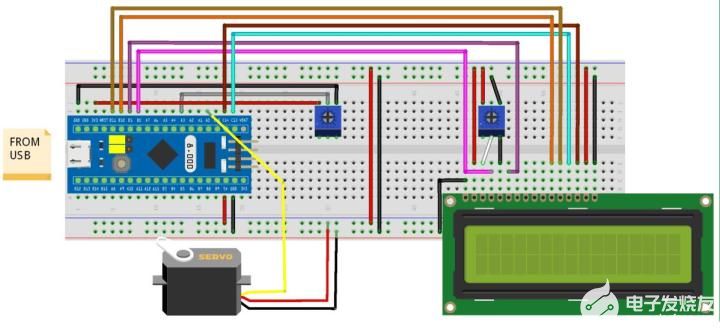

项目BOM表及电路连接

项目BOM表如下:

1、STM32F103C8蓝丸板 x1

2、伺服马达(SG90) x1

3、LCD(16x2) x1

4、电位器 x2

5、面包板 x1

6、跳线 若干

STM32F103C8有10路ADC引脚(PA0-PB1),本项目使用PA3作为analogread(),通过电位器设定马达的位置。在STM32引脚的15 PWM引脚中(PA0, PA1, PA2, PA3, PA6, PA7, PA8, PA9, PA10, PB0, PB1, PB6, PB7, PB8, PB9),我们只使用其中的一个引脚,为伺服马达的PWM引脚(该引脚通常带有颜色)提供脉冲信号。

STM32F103C8与LCD的连接如下:

STM32F103C8 LCD

GND VSS

+5V VDD

电位器中心PIN V0

PB0 RS

GND RW

PB1 E

PB10 D4

PB11 D5

PC13 D6

PC14 D7

+5V A

GND K

伺服马达与STM32F103C8的连接如下:

STM32F103C8 伺服马达

+5V RED (+5V)

PA0 ORANGE (PWM pin)

GND BROWN (GND)

本项目使用两个电位器:

(1)右边的用来改变LCD对比度。左边接5V电源,右边接地,中间引脚与LCD的V0连接。

(2)左边的用来模拟输入电压的大小,以改变伺服马达转子的位置。左边引脚接3.3V电源,右边接地,中间连接与的STM32板子的PA3引脚。

编程及代码说明

如果电脑安装了Arduino IDE,连接上USB接口,就可以像使用Arduino一样,对STM32F103C8进行编程了,无须使用FTDI编程器。

首先,载入马达和LCD函数:

#include

#include

其次,声明LCD显示器引脚并初始化。同时还要声明其他几个用于PWM和电位器的变量:

const int rs = PB0, en = PB1, d4 = PB10 , d5 = PB11 , d6 = PC13, d7 = PC14;

LiquidCrystal lcd(rs,en,d4,d5,d6,d7);

int servoPin = PA0;

int potPin = PA3;

这里,我们创建了伺服变量,并将其赋予前述声明的PWM引脚。

Servo servo;

servo.attach(servoPin);

然后,从ADC引脚——PA3读取模拟值,将模拟电压(0-3.3)转换成数字形式(0-4095)。

analogRead(potPin);

该ADC为12位,我们需要获得的0-170模拟值,要将其均分为(0-4096)数字形式。

angle = (reading/24);

下面指令使伺服马达以给定的角度旋转转轴:

servo.write(angle);

完整的代码如下:

//INTERFACE SERVO WITH STM32

//CIRCUIT DIGEST

#include //including servo library

#include //including LCD display library

const int rs = PB0, en = PB1, d4 = PB10 , d5 = PB11 , d6 = PC13, d7 = PC14; //declaring pin names and pin numbers of lcd

LiquidCrystal lcd(rs,en,d4,d5,d6,d7);//setting lcd and its paramaters

int servoPin = PA0; //declare and initialize pin for servo output PWM

int potPin = PA3; //potentiometer ADC input

Servo servo; // creating variable servo with datatype Servo

void setup()

{

lcd.begin(16,2); //setting lcd as 16x2

lcd.setCursor(0,0); //setting cursor at first row and first column

lcd.print("CIRCUIT DIGEST"); //puts CIRCUIT DIGEST in LCD

lcd.setCursor(0,1); //setting cursor at second row and first column

lcd.print("SERVO WITH STM32"); //puts SERVO WITH STM32 in LCD

delay(3000); // delays for 3 seconds

lcd.clear(); //clears lcd display

servo.attach(servoPin); //it connects pin PA0 with motor as control feedback by providing pulses

}

void loop()

{

lcd.clear(); //clears lcd

int angle; //declare varible angle as int

int reading; //declare varible reading as int

reading = analogRead(potPin); //read analog value from pin PA3

angle = (reading/24); //it divides ADC the value according to max angle 170 deg

servo.write(angle); //it puts angle value at servo

lcd.setCursor(0,0); //setting cursor at first row and first column

lcd.print("ANGLE:"); //puts ANGLE in LCD

lcd.print(angle); //puts value at angle

delay(100); //delay in time

- 相关推荐

- 热点推荐

- lcd

- 伺服马达

- 电路连接

- STM32F103C8

-

在STM32F103c8上做DLQR最优控制算法的C编程资料2025-07-23 209

-

将步进电机与STM32F103C8板连接的教程2022-11-07 9489

-

将伺服电机与STM32F103C8板连接起来的教程2022-11-04 3921

-

如何在STM32F103C8中使用中断2022-11-03 3667

-

使用ESP8266将STM32F103C8连接到互联网的方法2022-10-28 13827

-

如何使用STM32F103C8的GPS模块获取位置坐标2022-09-08 10038

-

在STM32F103C8微控制器中使用RS-485串行通信2022-09-06 9591

-

IAP在STM32F103C8上的实现2022-03-02 3914

-

STM32F103C8虚拟串口移植的实验代码该怎样去实现呢2022-02-24 1690

-

基于STM32F103C8 输入捕获实验2021-11-30 834

-

在STM32F103C8上实现一个简单的bootloader2021-11-23 1151

-

STM32F103C8的电路原理图免费下载2020-04-23 1754

-

stm32f103c82013-07-14 3579

-

STM32F103C82012-08-04 2172

全部0条评论

快来发表一下你的评论吧 !