KUKA-C4点焊机器人的控制(大众版)

描述

前言:

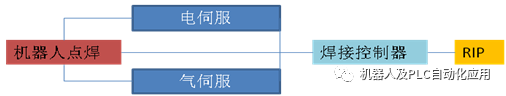

点焊机器人是大众标准中最常使用的基准工艺控制,它涉及到焊接控制,轨迹补偿控制,铣削夹紧控制,电极测量控制.还有虚拟轴软件控制,下面我会一一道来.

基础知识:

机器人使用气伺服焊钳要完成的工作:焊接,更换电极帽,铣削,开关水站RIP

点焊任务应在车辆坐标系(Base)中编程。

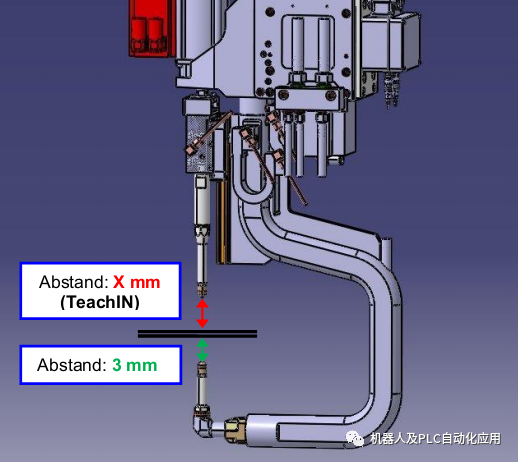

对于WPS机器人,电极与带有新E形帽的金属板之间的距离必须为3 mm,入射角必须为90度。SZ在关闭时不得滑动,在焊接时不得引起分流。

焊接点的坐标必须通过示教功能确定。

降压时不能使用示教功能。开口尺寸的计算方法如下:标准开口尺寸SZ +板材厚度+凸台高度。

对于带有补偿系统的焊枪,补偿值以二进制形式传输到焊枪,并且必须在每个焊接点进行编程。夹紧补偿的值应这样确定,使固定电极平缓地放在组件上。夹具补偿的值取决于夹具的类型和焊枪在焊接点的位置。

BIN2 ~ 焊钳 EZ1/SP1 平衡缸控制:

硬件设备的组态:

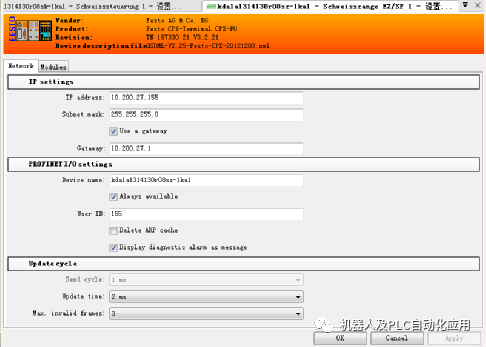

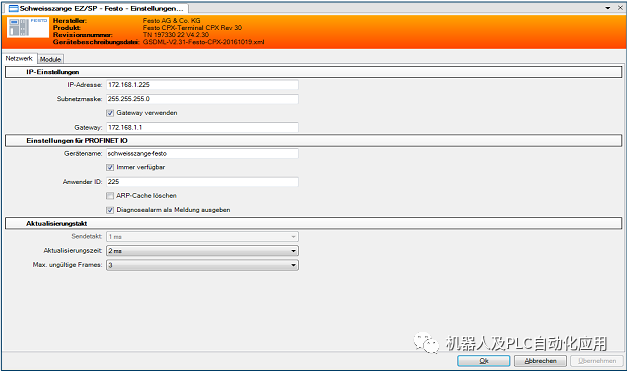

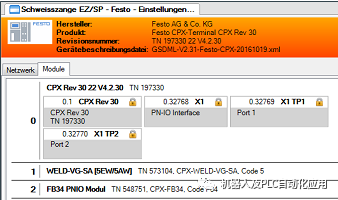

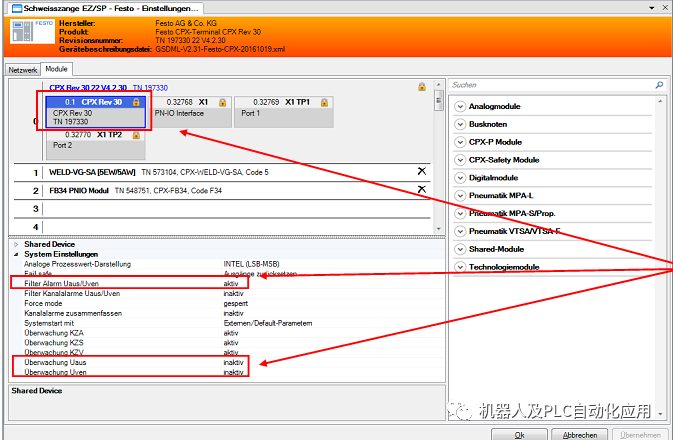

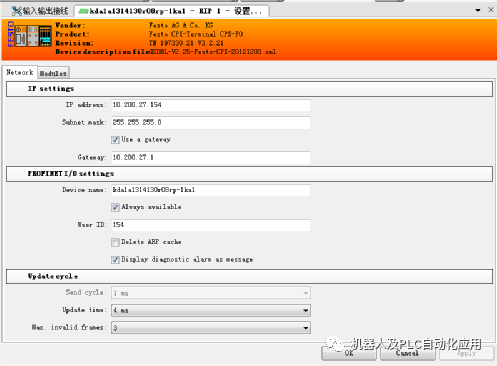

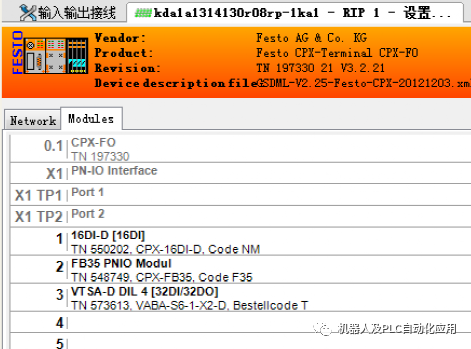

VASS06的FESTO伺服焊钳的网络配置:

输入信号

| E705 | Gun Ready | 准备就绪 |

| E706 | Energy saving is on | 节能开 |

| E707 | Release regulator is off | 释放调整关闭 |

| E708 | with force | 带压力 |

| E709 | Handshake bit TCP OK | 握手TCP位 OK |

| E710 | ||

| E711 | Teach position valid | 有效位置值 |

| E712 | Control manual | 手动控制 |

| E713 | Control automatic | 自动控制 |

| E714 | Gun is referenced | 焊钳在参考点 |

| E715 | Positioning active | 位置激活 |

| E716 | Actual positon valid | 实际的位置值 |

| E717 | Gun opened | 焊钳打开 |

| E718 | Force reached | 夹紧压力到达 |

| E719 | Equalizer is back | 平衡气缸返回 |

| E720 | ||

| E721 | Actual value E-Force v1*100N | 实际焊接压力 |

| E722 | Actual value E-Force v2*100N | |

| E723 | Actual value E-Force v4*100N | |

| E724 | Actual value E-Force v8*100N | |

| E725 | Actual value E-Force v16*100N | |

| E726 | Actual value E-Force v32*100N | |

| E727 | Actual value E-Force v64*100N | |

| E728 | Actual value E-Force v128*100N | |

| E729 | Offset fixed E-Arm 1*0.1mm | 焊枪磨损偏移量 |

| E730 | Offset fixed E-Arm 2*0.1mm | |

| E731 | Offset fixed E-Arm 4*0.1mm | |

| E732 | Offset fixed E-Arm 8*0.1mm | |

| E733 | Offset fixed E-Arm 16*0.1mm | |

| E734 | Offset fixed E-Arm 32*0.1mm | |

| E735 | Offset fixed E-Arm 64*0.1mm | |

| E736 | Offset fixed E-Arm 128*0.1mm | |

| E737 | Actual position v 1*0.1mm | 实际位置值 |

| E738 | Actual position v 2*0.1mm | |

| E739 | Actual position v 4*0.1mm | |

| E740 | Actual position v 8*0.1mm | |

| E741 | Actual position v 16*0.1mm | |

| E742 | Actual position v 32*0.1mm | |

| E743 | Actual position v 64*0.1mm | |

| E744 | Actual position v 128*0.1mm | |

| E745 | Actual position v 256*0.1mm | |

| E746 | Actual position v 512*0.1mm | |

| E747 | Actual position v 1024*0.1mm | |

| E748 | Actual position v 2048*0.1mm | |

| E749 | Actual position v 4096*0.1mm | |

| E750 | Actual position v 8192*0.1mm | |

| E751 | Actual position v 16384*0.1mm | |

| E752 | Actual position sign(0=pos/1=neg) | |

| E753 | Life bit gun controller | |

| E754 | ||

| E755 | Cap change OK | 更换电极帽完成 |

| E756 | ||

| E757 | End of measuring | 测量结束 |

| E758 | ||

| E759 | Milling OK | 修磨OK |

| E760 | ||

| E761 | Invalid gun code | 无效的焊钳代码 |

| E762 | ||

| E763 | ||

| E764 | ||

| E765 | ||

| E766 | Device code v1 | 设备码V1 |

| E767 | Device code v2 | 设备码V2 |

| E768 | Device code v4 | 设备码V4 |

| E769 | Pre warning gun | 焊枪预警 |

| E770 | Warming lubrication required | 加油要求警告 |

| E771 | Reaching force take too long | 压力到达超时 |

| E772 | Wrong program/force from robi | 机器错误的程序/力值 |

| E773 | Target position invalid | 目标位置无效 |

| E774 | component/plate thickness fail | 板材厚度故障 |

| E775 | Gun moving tightly | 焊钳移动固定 |

| E776 | Milling no OK | 修磨未完成 |

| E777 | Failure cap abrasion | 修磨电极帽故障 |

| E778 | Error caps/geometry | 电极帽故障 |

| E779 | Positioning deviation | 位置偏差 |

| E780 | Error equalizer | 平衡缸故障 |

| E781 | Error control/regulator | 控制/调整故障 |

| E782 | Error temperature transformer | 变压器温度故障 |

| E783 | Error pressure low | 压力过低 |

| E784 | Common error | 普通故障 |

输出信号

| A705 | Error reset | 故障复位 |

| A706 | Energy saving on | 节能模式打开 |

| A707 | Release regulator off | 释放调整关闭 |

| A708 | Without force | 不带压力 |

| A709 | With TCP correction | 带TCP修正 |

| A710 | Start learning teach position | 开始示教位置 |

| A711 | Take over teach position | 接受示教位置 |

| A712 | Robot manual | 机器人手动 |

| A713 | Robot automatic | 机器人自动 |

| A714 | Reference | 寻参 |

| A715 | Release positioning | 定位使能 |

| A716 | Set position valid | 定位设定有效 |

| A717 | Open gun | 开枪 |

| A718 | Close gun | 关枪 |

| A719 | Gun jog open | 点动开枪 |

| A720 | Gun jog close | 点动关枪 |

| A721 | Set value E-Force v1*100N | 设置焊接压力值 |

| A722 | Set value E-Force v2*100N | |

| A723 | Set value E-Force v4*100N | |

| A724 | Set value E-Force v8*100N | |

| A725 | Set value E-Force v16*100N | |

| A726 | Set value E-Force v32*100N | |

| A727 | Set value E-Force v64*100N | |

| A728 | Set value E-Force v128*100N | |

| A729 | Equalizer pressure v1 | 平衡缸压力设定 |

| A730 | Equalizer pressure v2 | |

| A731 | Equalizer pressure v4 | |

| A732 | Equalizer pressure v8 | |

| A733 | Equalizer pressure v16 | |

| A734 | Equalizer pressure v32 | |

| A735 | Equalizer pressure v64 | |

| A736 | Equalizer pressure v128 | |

| A737 | Set position v 1*0.1mm | 位置设定 |

| A738 | Set position v 2*0.1mm | |

| A739 | Set position v 4*0.1mm | |

| A740 | Set position v 8*0.1mm | |

| A741 | Set position v 16*0.1mm | |

| A742 | Set position v 32*0.1mm | |

| A743 | Set position v 64*0.1mm | |

| A744 | Set position v 128*0.1mm | |

| A745 | Set position v 256*0.1mm | |

| A746 | Set position v 512*0.1mm | |

| A747 | Set position v 1024*0.1mm | |

| A748 | Set position v 2048*0.1mm | |

| A749 | Set position v 4096*0.1mm | |

| A750 | Set position v 8192*0.1mm | |

| A751 | Set position v 16384*0.1mm | |

| A752 | Set position sign(0=pos/1=neg) | 位置设定符号(0=正/1负) |

| A753 | Life bit Robot | 机器人通讯有效 |

| A754 | Compensation Robot | 机器人补偿 |

| A755 | Cap changed | 更换电极帽 |

| A756 | Meas.before milling | 打磨前测量 |

| A757 | Meas .after milling | 打磨后测量 |

| A758 | Start milling done | 首次修磨后完成 |

| A759 | Normal milling done | 过程修磨后完成 |

| A760 | Test without componet | 无工件测试 |

| A761 | Gun code 1 | 焊枪代码1 |

| A762 | Gun code 2 | 焊枪代码2 |

| A763 | Gun code 4 | 焊枪代码4 |

| A764 | Gun code spare | 备用焊枪号码 |

| A765 | 诊断 功能 | |

| A766 | ||

| A767 | ||

| A768 | ||

| A769 | Program W1 | 程序号 |

| A770 | Program W2 | 程序号 |

| A771 | Program W4 | 程序号 |

| A772 | Program W8 | 程序号 |

| A773 | Program W16 | 程序号 |

| A774 | Program W32 | 程序号 |

| A775 | Program W64 | 程序号 |

| A776 | Program W128 | 程序号 |

| A777 | Vehicle type v1 | 类型号 |

| A778 | Vehicle type v2 | 类型号 |

| A779 | Vehicle type v4 | 类型号 |

| A780 | Vehicle type v8 | 类型号 |

| A781 | Vehicle type v16 | 类型号 |

| A782 | Vehicle type v32 | 类型号 |

| A783 | Vehicle type v64 | 类型号 |

| A784 | Vehicle type v128 | 类型号 |

在分配焊钳的IO地址是 E/A737à752

VASS06的版本:

GSDML-V2.31-Festo-CPX -20161019.xml

停用US2诊断并在设备上显示红色错误LED

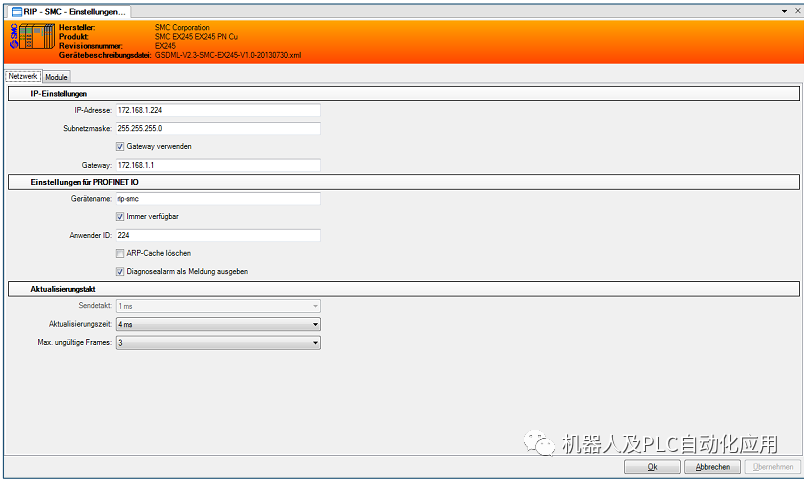

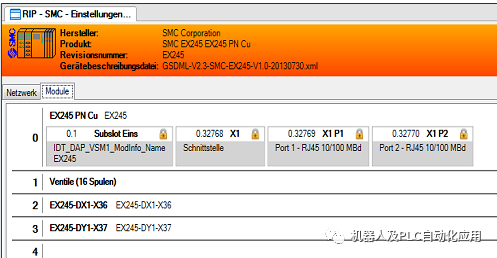

使用SMC的水气站RIP - SMC

RIP1的IO区域: 513-520

E513 K1水流量合格 A513 KYP01AE 开水

E514 BV01WMIN 水流量低位检测(NO高于低压值才有信号)

E515 BV01WMAX 水流量高位检测 (NC 超过高压没有信号) A515 KYP01AA 关水

E516 BD01ND 低压气合格

GSDML -V2.3 -SMC -EX245 -V1.0 -20130730.xml

FESTO的RIP设置:

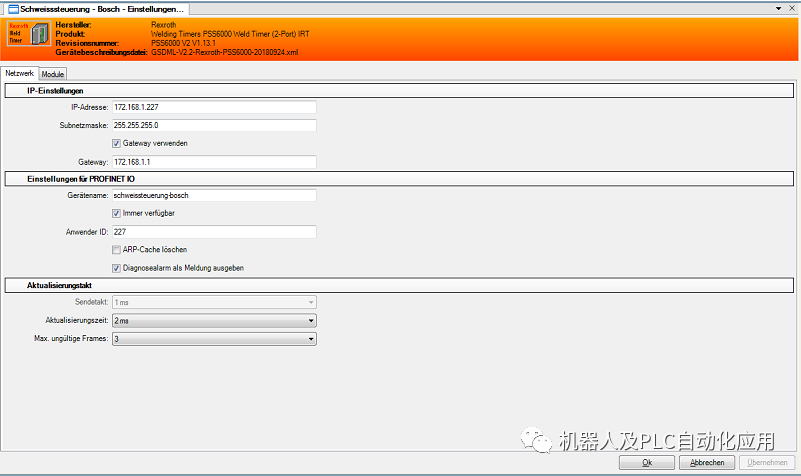

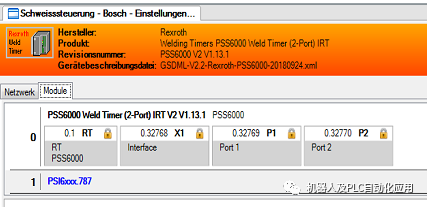

使用BOSCH焊接控制器:

| E785 | Weld complete | 焊接完成 |

| E786 | Tip dress request | 当前修磨请求 |

| E787 | Tip dress counter reset | 修磨次数清零、复位 |

| E788 | Start tip dress request | 首次修磨 |

| E789 | Tip dressing necessary | 有两把枪,一把需要修磨的时候 |

| E790 | With tip dressing seleted | 已选择修磨 |

| E791 | Tip changing prewarning | 电极寿命报警 |

| E792 | Weld on(with welding cuttent) | 开始焊接 |

| E793 | Target electrode force valency 1 | 电极压力目标值 |

| E794 | Target electrode force valency 2 | |

| E795 | Target electrode force valency 4 | |

| E796 | Target electrode force valency 8 | |

| E797 | Target electrode force valency 16 | |

| E798 | Target electrode force valency 32 | |

| E799 | Target electrode force valency 64 | |

| E800 | Target electrode force valency 128 | |

| E801 | End of stepper | 结束热量递增 |

| E802 | Timer ready | 控制器准备好 |

| E803 | With monitoring | 带电流监控 |

| E804 | Weld OK | 焊接完成 |

| E805 | Weld no OK | 焊接未完成 |

| E806 | Warning limit consecutively violated | 连续九点偏离中间公差带 |

| E807 | Proportional valve pressure reached | 阀的压力达到要求 |

| E808 | Differential current monitoring tripped | 电流监控 |

| E809 | Phase monitoring | 相位监控 |

| E810 | Overcurrent on primary side | 初级线圈过流 |

| E811 | Current sensor error | 电流传感器错误 |

| E812 | Voltage sensor error | 电压传感器错误 |

| E813 | Overcurrent 24V DC | 24V过载 |

| E814 | Inverter Overtemperature | 变压器温度过高 |

| E815 | Spot selection error | 焊点选择错误 |

| E816 | Protocol write error | 记录错误 |

| E817 | Reserviert | 预留 |

| A785 | Start | 焊接开始 |

| A786 | Tips have been dressed | 电极已修磨 |

| A787 | Electrodes have been changed | 电极已更换 |

| A788 | Reset fault | 普通故障复位(三相380) |

| A789 | Reset fault with WC | 控制器故障复位 |

| A790 | Start recording protocol | 开始记录电流 |

| A791 | Function test without component | 无件测试 |

| A792 | Weld on(with welding current) | 焊接打开,带电流焊接 |

| A793 | feedback electrode force valency 1 | 电极压力反馈 |

| A794 | feedback electrode force valency 2 | |

| A795 | feedback electrode force valency 4 | |

| A796 | feedback electrode force valency 8 | |

| A797 | feedback electrode force valency 16 | |

| A798 | feedback electrode force valency 32 | |

| A799 | feedback electrode force valency 64 | |

| A800 | feedback electrode force valency 128 | |

| A801 | Spot selection valency 1 | 焊点选择值 |

| A802 | Spot selection valency 2 | |

| A803 | Spot selection valency 4 | |

| A804 | Spot selection valency 8 | |

| A805 | Spot selection valency 16 | |

| A806 | Spot selection valency 32 | |

| A807 | Spot selection valency 64 | |

| A808 | Spot selection valency 128 | |

| A809 | Spot selection valency 256 | |

| A810 | Spot selection valency 512 | |

| A811 | Spot selection valency 1024 | |

| A812 | Spot selection valency 2048 | |

| A813 | Spot selection valency 4096 | |

| A814 | Spot selection valency 8192 | |

| A815 | Spot selection valency 16384 | |

| A816 | Spot selection valency 32768 | |

| A817 | Ident valency 1 | 车型选择 |

| A818 | Ident valency 2 | |

| A819 | Ident valency 4 | |

| A820 | Ident valency 8 | |

| A821 | Ident valency 16 | |

| A822 | Ident valency 32 | |

| A823 | Ident valency 64 | |

| A824 | Ident valency 128 | |

| A825 | Reserviert | 预留 |

GSDML-V2.2 -Rexroth-PSS6000 -20180924.xml

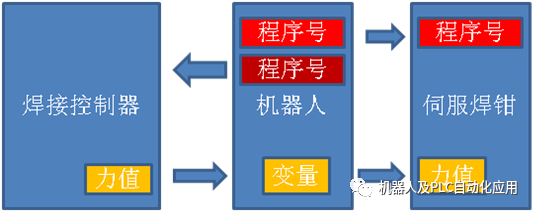

机器人控制逻辑图:

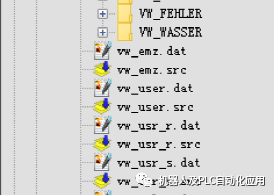

使用的KRL语言的高级程序:

feh_usr_s.src 提示机器人设备故障:以水流量为主

可以在每个焊接点调用该技术包。通过该调用,一方面根据盖的磨损将TCP临时更改为–X,另一方面根据参数P3“偏移”的值将TCP更改为–X。通过参数P4“距离”,可以选择指定在点PLC处理之后在循环中执行的提升值。这样可以去除以前使用过的组件上的磨痕

中间点或距离大于固定E臂的3mm 焊接点在单步MSTEP模式下编程,无TCP移位且无参数4,因此可以检查或更改固定E臂的编程距离。在单步GO操作中,使用TCP移位和参数4。

常用MAKRO的用法

Makro80 焊接

Makro81 维修位置/更换电极确认

审核编辑 :李倩

-

点焊机程序2024-04-25 16661

-

LED灯丝点焊机 LED灯丝碰焊机 上下对焊机 五金点焊机 金属碰焊机2024-02-16 4915

-

KUKA-C4点焊机器人的控制原理2023-05-11 2152

-

怎么解决精密点焊机出现点焊强度不足的问题?2023-02-28 1509

-

点焊机器人的工作原理以及应用2023-02-02 2365

-

点焊机器人的使用寿命2022-12-01 1762

-

气动点焊机的发展与类别2022-11-25 3461

-

精密点焊机的操作方式都有哪些?2022-06-28 12658

-

点焊机器人的工作原理及应用2022-04-06 5362

-

点焊机器人的组成及应用2020-12-26 2560

-

点焊机器人工作原理_点焊机器人的应用2019-10-15 10706

-

机器人焊接技术在车身焊接工艺的应用2018-11-01 2522

全部0条评论

快来发表一下你的评论吧 !