驱动和保护电源开关的高级解决方案

电源/新能源

描述

如今,新的功率开关技术正被广泛应用于要求高功率密度、高开关频率和小尺寸是关键要求的苛刻应用中。这些新开关器件发挥作用的三个关键应用是:

汽车(牵引逆变器、DC/DC 转换器和车载充电器)

工业/电机控制(负载点电源、不间断电源、机器人、电机控制)

电源/太阳能(太阳能逆变器、电信电源、服务器/云/PC电源)

功率开关要么使用传统的硅基技术制造,例如MOSFET和绝缘栅双极晶体管 (IGBT),要么使用更新的宽带隙半导体制造,例如碳化硅和氮化镓。在相关应用中,汽车是近年来发展势头强劲的领域,主要是由于正在向电动汽车过渡以及电动汽车的逐步采用。

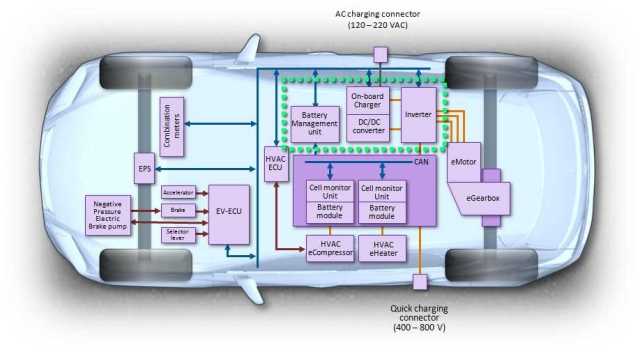

如图 1 所示,电动汽车集成了大量传感器和电子电路,包括高压总线(400 V、800 V 或更高)和本地低压总线。SiC 器件正在取代高压系统中的硅基器件,例如车载充电器、电池管理系统、主 DC/DC 转换器和牵引逆变器。

图 1:电动汽车系统中的开关技术

高压母线存在严重的安全问题,它必须与低压母线电隔离,同时仍允许在两个电压域之间双向交换信息。

Skyworks 隔离栅极驱动器

Skyworks Solutions 是一家为无线网络应用提供高度创新的模拟半导体的领先公司,最近完成了对 Silicon Labs 基础设施和汽车业务的收购。针对包括电动汽车和混合动力汽车在内的关键汽车领域的增长,Skyworks 为硅、GaN 和 SiC 电源开关提供高性能和强大的隔离式栅极驱动器。

Skyworks Solutions 产品经理 Charlie Ice 在 2021 年 PowerUP Expo 上举行了关于“驱动和保护未来的电源开关”的技术演讲,讨论了硅基和宽带隙功率器件的关键栅极驱动器要求和保护方法. 本文将介绍相同的主题。

“特别是在电动汽车中,我们必须确保高压侧和低压侧保持隔离,同时确保它们仍然可以通过该屏障进行通信和信息交换,”查理说。

隔离器件的特性对于 SiC 和 GaN 等新的开关技术更为重要,它们可以实现更高的效率,但更敏感,更容易损坏。因此,这些新的开关技术需要独特的保护才能安全可靠地运行。

传统上,电力电子系统依赖于 IGBT,这是在高功率和高电压条件下每瓦成本最低的解决方案。然而,IGBT 的开关速度较慢,从而限制了系统的效率。这就是 SiC 和 GaN 都介入以真正推动更高效率的地方。两者的一个缺点是它们不能像 IGBT 那样承受尽可能多的故障条件,这就是它们需要额外保护的原因。

在高压系统中,为了安全起见,我们必须将高压侧与低压侧分开。通常,设计人员决定将控制器保持在低压侧,以便远离噪声和大瞬态。控制器生成脉宽调制 (PWM) 信号,并将它们穿过隔离栅传递到栅极驱动器,该驱动器基本上将低压 PWM 信号放大为能够打开和关闭功率器件的更高信号。

隔离式栅极驱动器执行的两个主要功能是将 3V 或 5V 信号电平转换到 24V 或 30V 的较高电压轨,并提供开关电流以对栅极电容器进行充电/放电。通过添加电流隔离屏障,该器件实现了两个主要优点:

It provides input-to-output isolation for protection of the controller, and perhaps personnel, from high voltages and voltage transients.

It helps to maintain noise-immune operation for best efficiency. High-voltage transients can disrupt operation, resulting in loss of modulation and thus efficiency.

The isolated gate driver can be safely used to switch even high-power switches, such as silicon or superjunction MOSFETs, IGBTs, and wide-bandgap switches like GaN and SiC. Isolated gate drivers are available in many flavors: single-channel, dual-channel, and ones that can generate a high-side and a low-side signal from a single PWM input.

“I typically find that many automotive systems use single-channel drivers because they make the board-layer layout easier; however, dual-channel drivers and high-side/low-side drivers are very popular in power supply systems,” said Charlie.

Regarding protection, one of the key methods is the Miller clamp. Its function is to monitor the voltage on the gate, and if it gets too high, it clamps it. Basically, it’s an active monitor to ensure the gate is always off. However, Miller clamp protection is not enough for SiC and GaN power devices, which are more sensitive and get damaged more quickly. The other feature we need to add for driving SiC or GaN devices, improving their protection and longevity, is desaturation detection and soft shutdown.

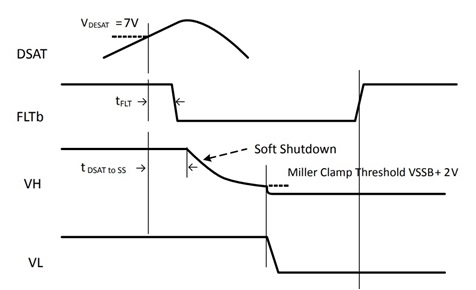

In a high-power system, such as a traction inverter, it’s not uncommon that power devices experience a momentary overcurrent condition. In this case, an isolated gate driver with desat detection can monitor the voltage (VCE) across the power switch. If it detects too much voltage across it (see Figure 2), which would indicate a fault condition, it automatically shuts it off in a very safe way, also known as soft shutdown. However, it is important to set the device off quickly enough to avoid being damaged. Here, we can see how switching devices behave differently. An IGBT, for instance, needs to be turned off within 3 µs, while a SiC device needs to be shut down within 1.2 µs and a GaN device within 200 ns.

Figure 2: Desaturation protection with fault indication

“这两项关键技术——米勒钳位和去饱和检测——对于成功驱动 SiC 和 GaN 以及使系统可靠并且在许多方面安全,已经变得非常关键,”Charlie 说。

审核编辑:刘清

-

如何计算电源开关管保护电路参数2019-03-21 0

-

电源开关管的过压保护电路2019-03-22 0

-

以单通道电源开关提高USB的端口保护2010-01-14 758

-

电源开关怎么安装2019-04-10 18447

-

为什么说kb0开关产品是电源开关的保护伞2021-02-01 806

-

我们常见的双电源开关都有哪些2021-03-08 2710

-

降低电源开关输入电压尖峰的解决方案2022-04-20 8847

-

驱动器和 SiC MOSFET 打开电源开关的大门2023-01-03 695

-

电源开关选型标准,电源开关选型规范注意事项2023-07-14 5168

-

电源开关怎么选型号参数,电源开关选型怎么选2023-07-14 6015

-

电源开关器件讲解(1)2023-10-21 1063

-

简述集成电源开关保护方案2023-10-27 1051

-

bsp452电源开关ic工作原理2023-12-22 940

-

上电期间电源开关故障毛刺解决方案2024-09-25 249

全部0条评论

快来发表一下你的评论吧 !