极片&复合基材电阻 (Gen & Magic系列)

电子说

描述

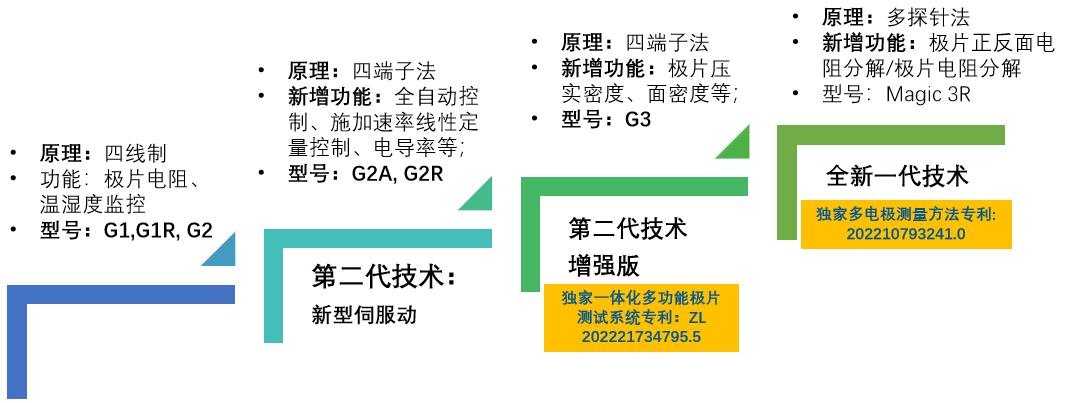

膜片电阻产品发展历程

2016年9月,川源科技前身推出“全球首款”极片电阻测试仪; 2017年3月,川源科技公司成立,正式发布G1系列极片电阻产品; 2020年9月,发布 “全闭环式伺服气动控制系统”及G2系列产品; 2021年4月,发布“新一代全闭环伺服电动控制系统”丰富产品系列; 2022年6月,发布全球首款一键式极片面密度、压实密度、厚度、电导率的G3系列产品; 2022年7月,发布全球首款“多电极极片电阻测试系统Magic系列”-实现极片面电阻分解测量;

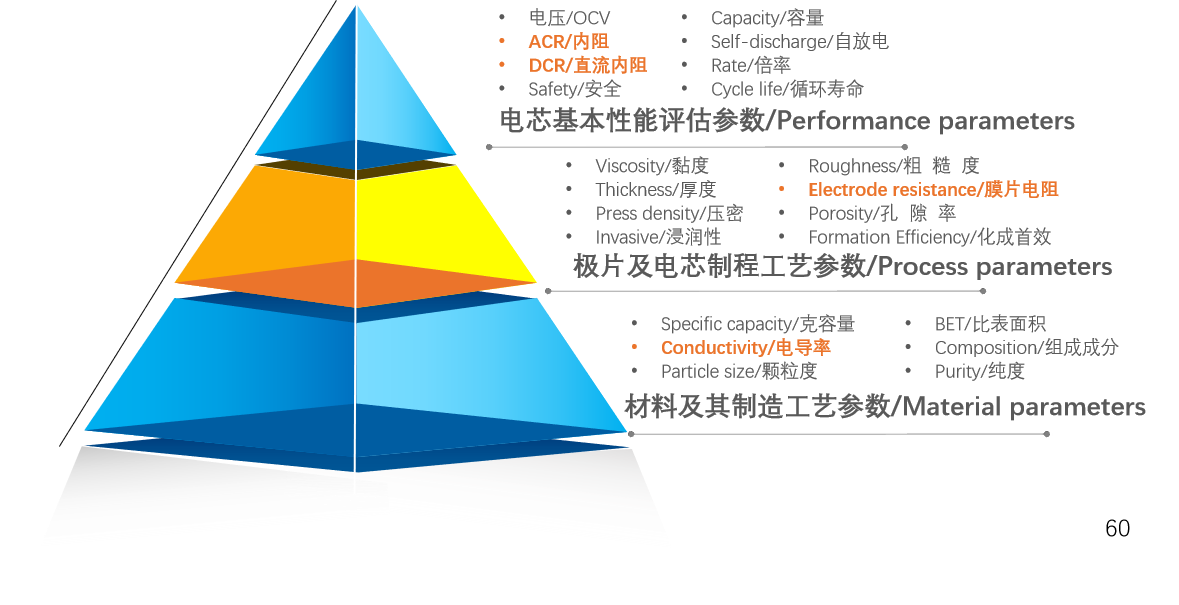

锂电池开发 VS. 电阻值参数

L3:极片电阻测试的必要性

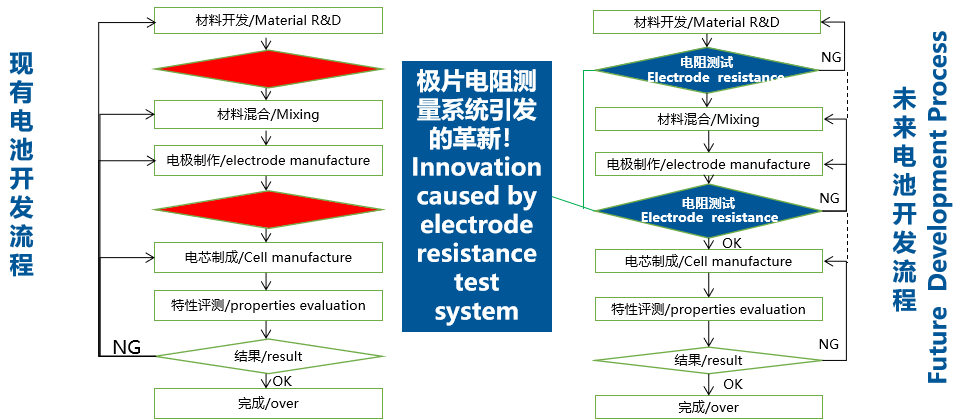

当前,极片电阻的评价研发与生产中逐渐成为主流,主要基于其在提高电池开发效率与生产可靠性及降低降低开发与生产成本方面;

The evaluation of electrode resistance has gradually become the mainstream in R&D and production. It is mainly based on the improvement of R&D efficiency and Manufacturing reliability.

技术发展迭代

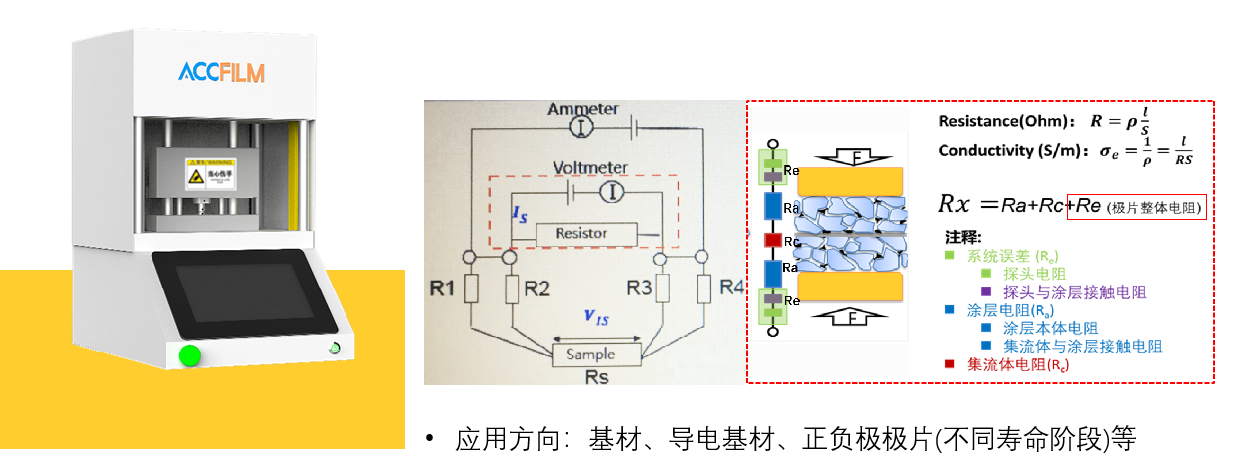

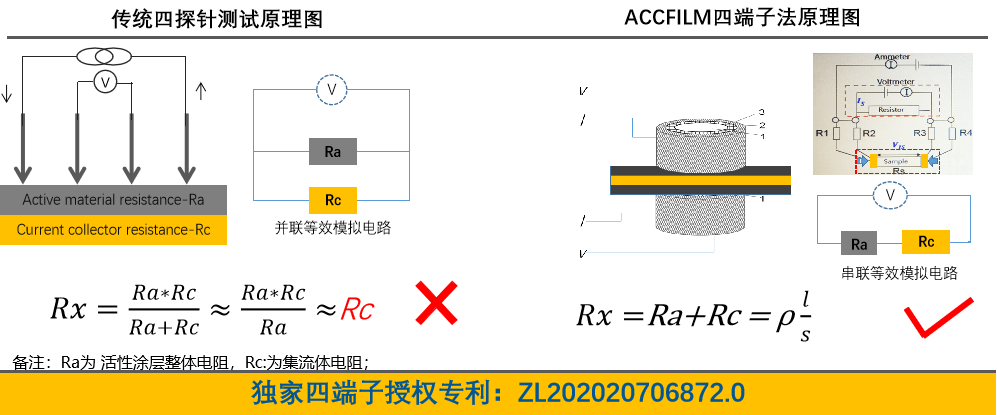

基材/极片电阻测试原理

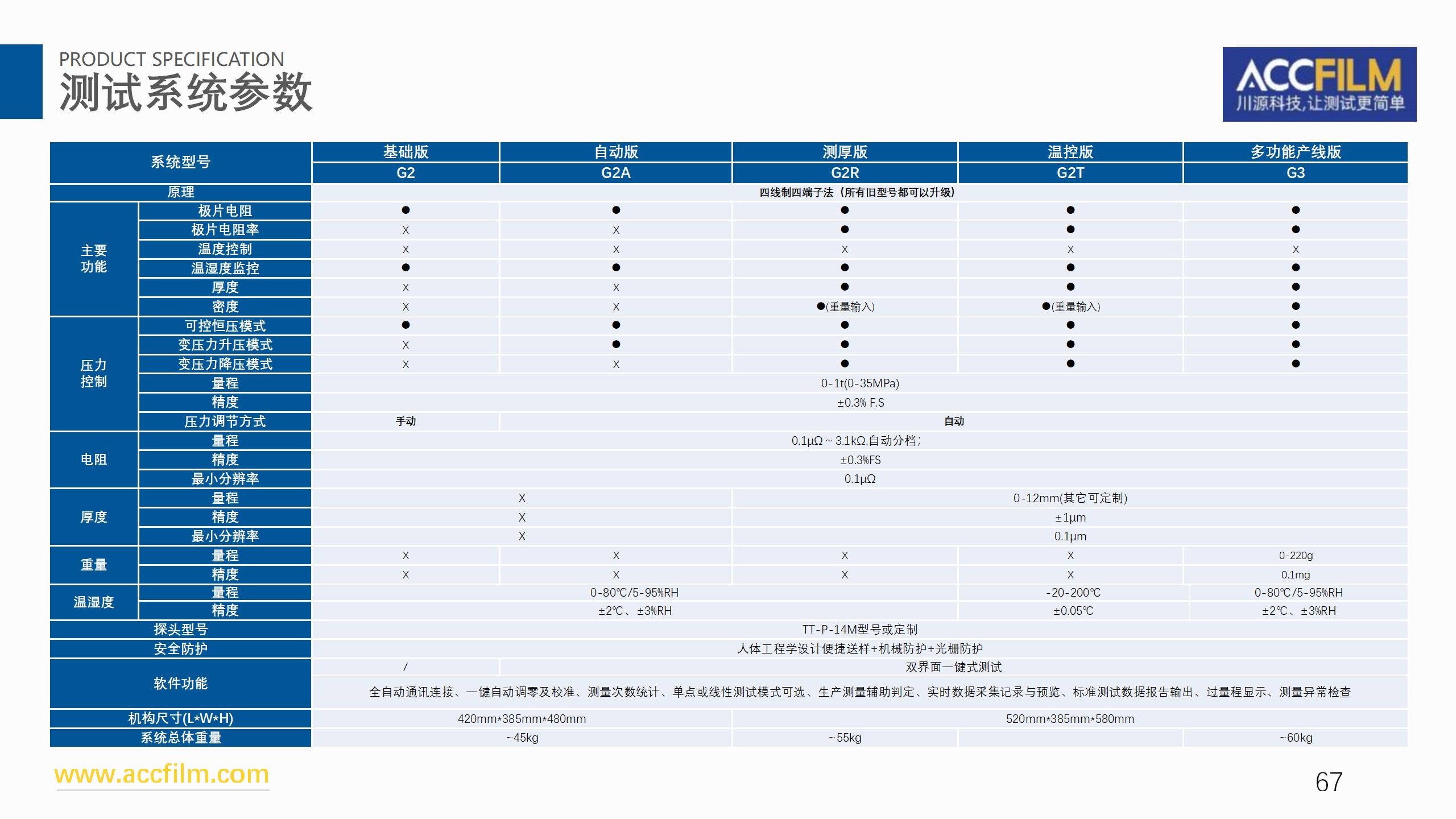

采用可控压四线制双探头电阻法,基于高精度位移、电压电流、压力、温湿度传感,实现持续、精准、稳定监测极片极致条件下电阻特性。

解决方案1:极片整体电阻测试(G2, G2A, G2R)

相比于传统四探针,ACCFILM的四端子测试方法(排除接触电阻)才适用于膜片电阻测试。

Compared with the traditional four probe, the strategy of ACCFILM electrode resistance test system is really suitable for battery electrode resistance test.

解决方案2:底涂电阻&面密度等综合测试系统(G3)

ACCFILM膜片电阻测试系统集成高精密质量传感器,实现极片电阻、厚度、压实密度、面密度等多参数测量一站式测量,综合效率提高60%y以上,成本降低60%以上(四个测试工序合并成一个)。

The ACCFILM test system integrates high-precision quality sensors to realize one-stop measurement of electrode resistance, thickness, and density, which greatly improves test efficiency(>60%).

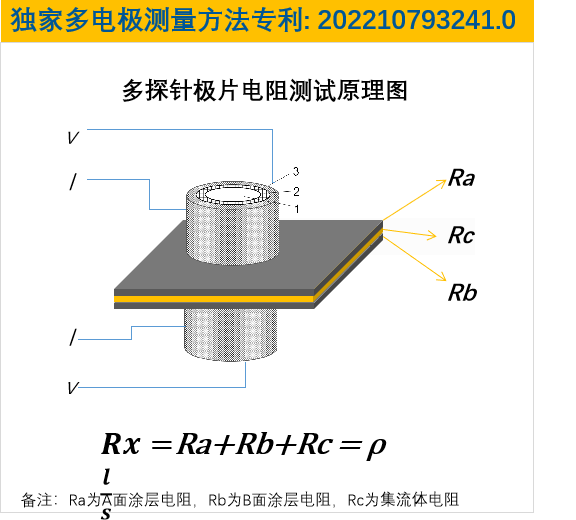

解决方案3:极片整体电阻测试&涂层电阻分解 (Magic 3R)

基于电极极片的多层结构,通过在四端子测量法的基础上新增测量电极,形成全新的多电极测量方案,首次实现极片整体电阻及极片涂层电阻的分解,为极片电阻评估提供新的方法。

Based on the structure of the electrode, a new multi-probe measurement scheme is formed by adding a measuring probe on the basis of the four-probe method, which realizes the decomposition of electrode resistance for the first time, and provides a new method for the evaluation of the polar resistance.

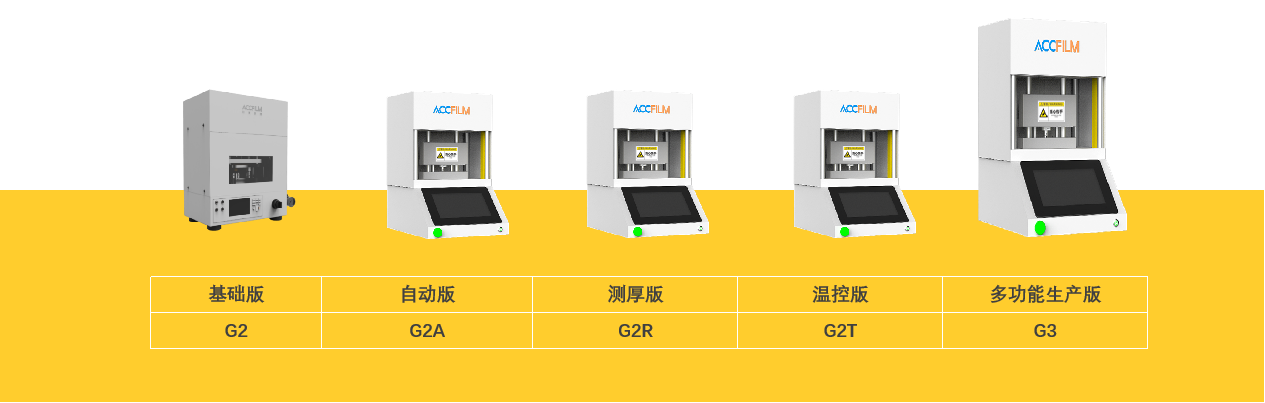

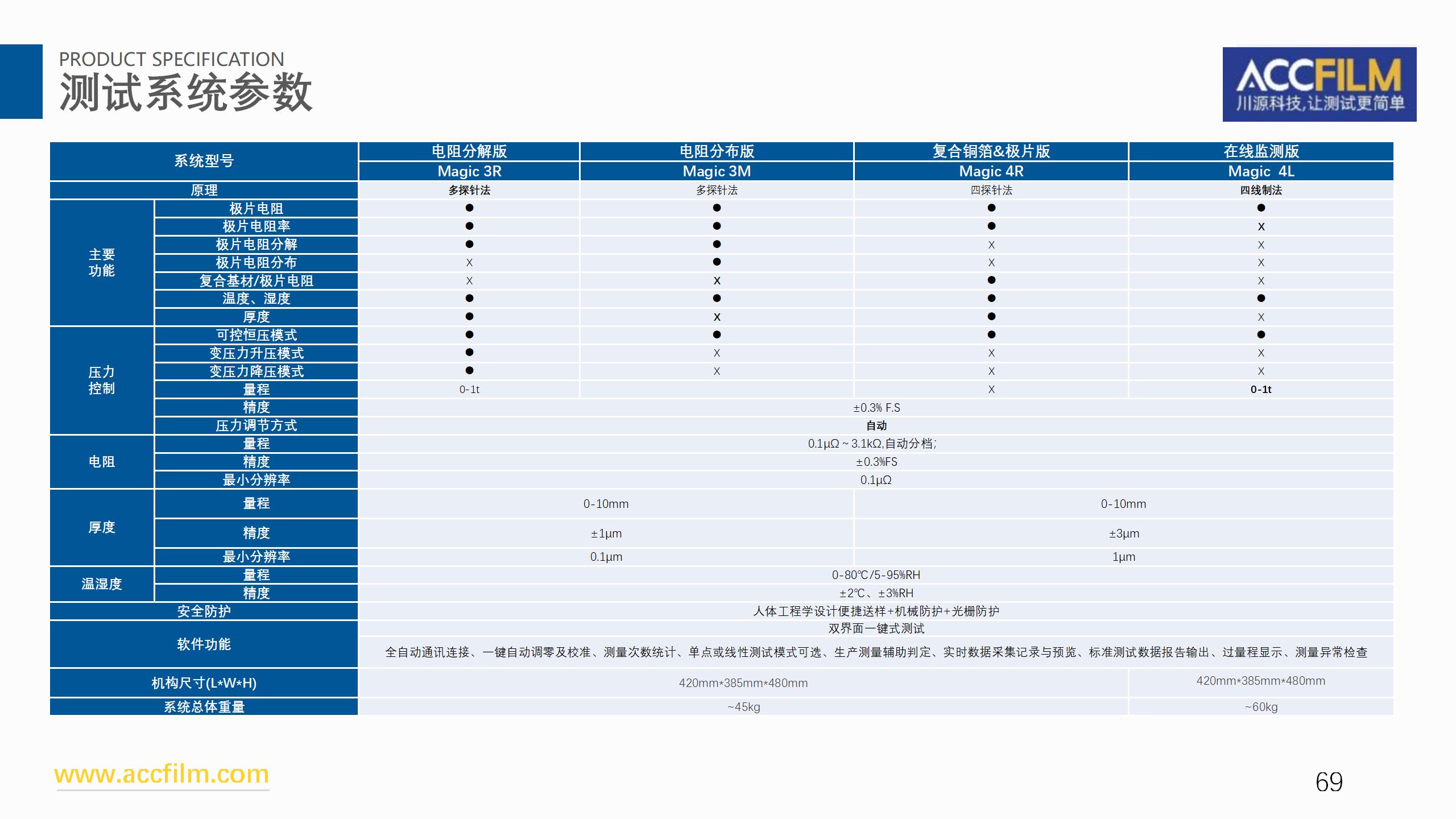

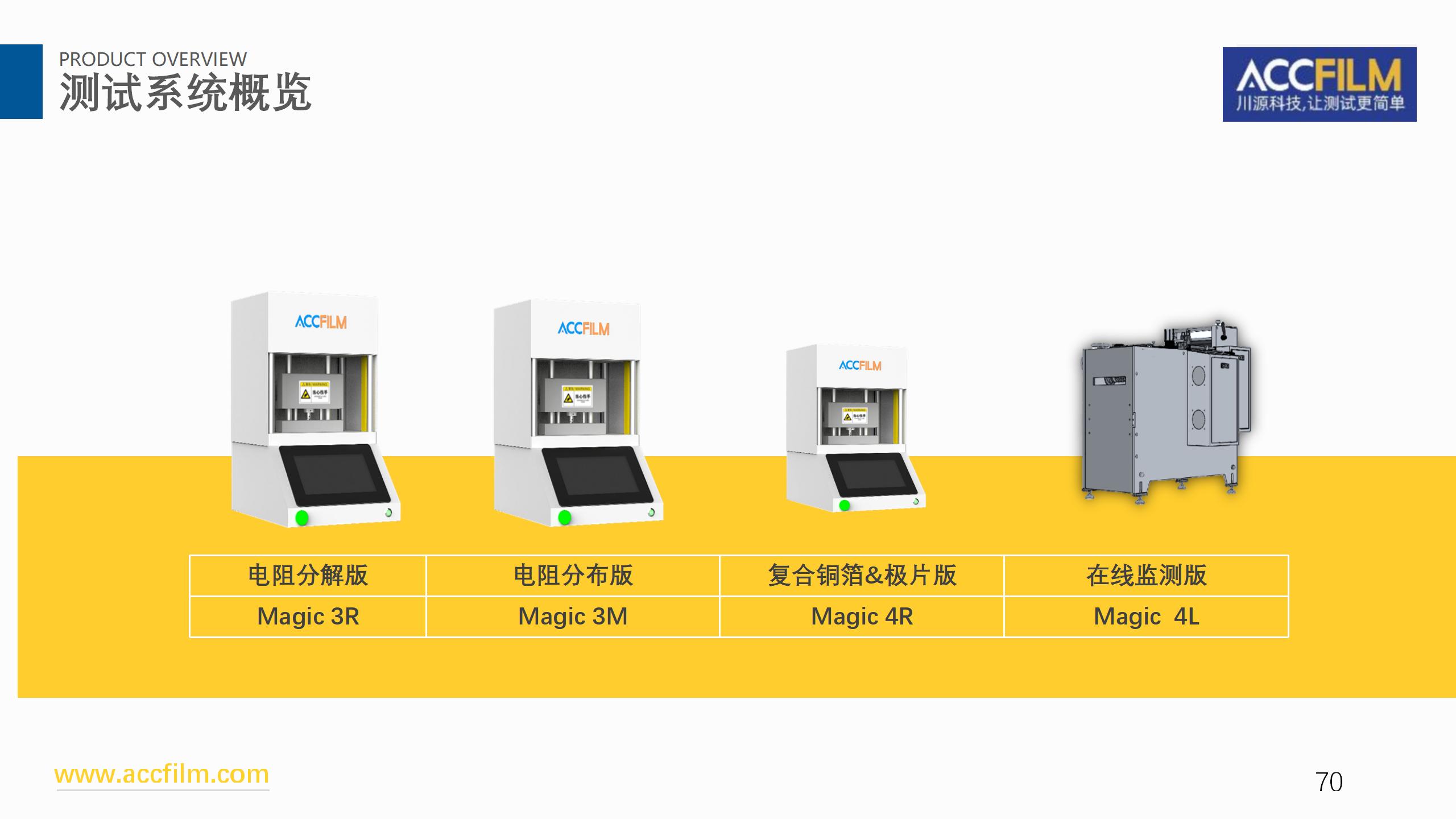

测试系统概览

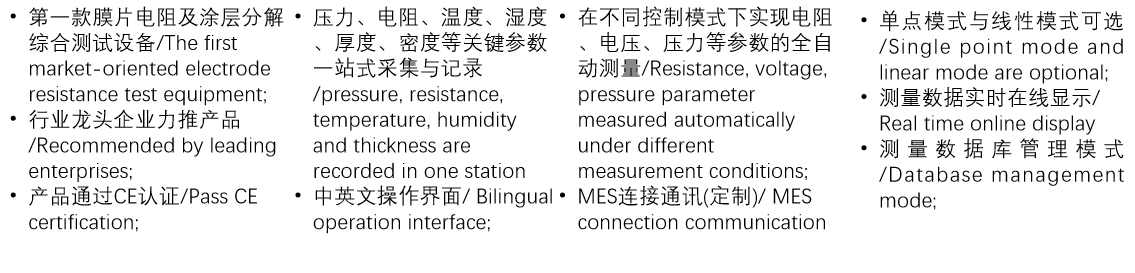

产品特色与优势Features and Advantages

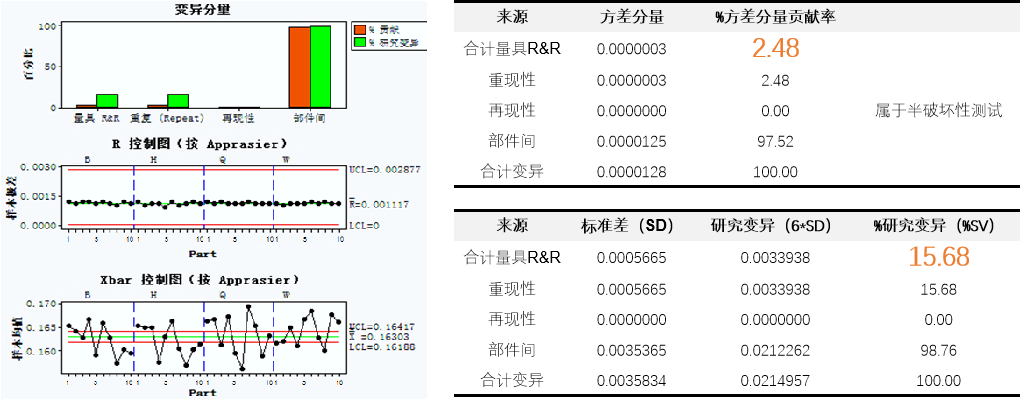

可靠性分析(R&R)

R&R可区分的类别数为8;(一般≥5即表示测量系统可接受)

The number of distinguishable R & R categories is 8( Generally ≥ 5 means the measurement system is acceptable);

应用领域与方向

锂电池、超级电容器等二次电池相关领域的生产制造企业、大学及科研院所科研及生产过程;

Manufacturing enterprises, universities and scientific research institutes of lithium battery, supercapacitor and other secondary battery related fields;

涂炭基材开发评估与生产环境控制参数指导

精准测量底涂技术开发膜片的电阻变化,为极片工艺开发提供有力技术支持;

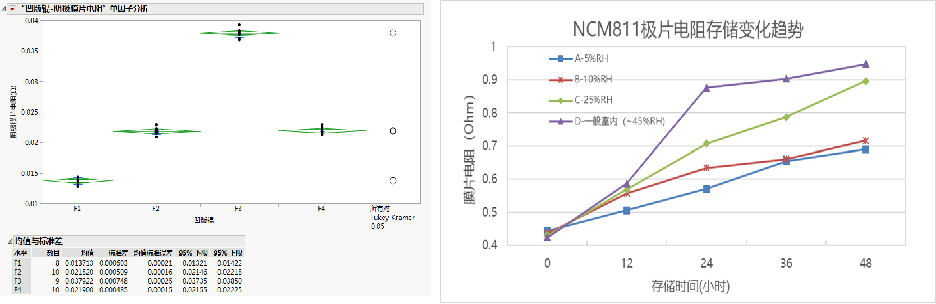

通过研究膜片在不同湿度存储后的膜片电阻值,来为生产确定工序控制时间做数据支撑。以下实例可以看出,811膜片的存储越低湿度越有利于膜片的稳定性10%RH的湿度可考虑用于811体系的生产控制湿度。

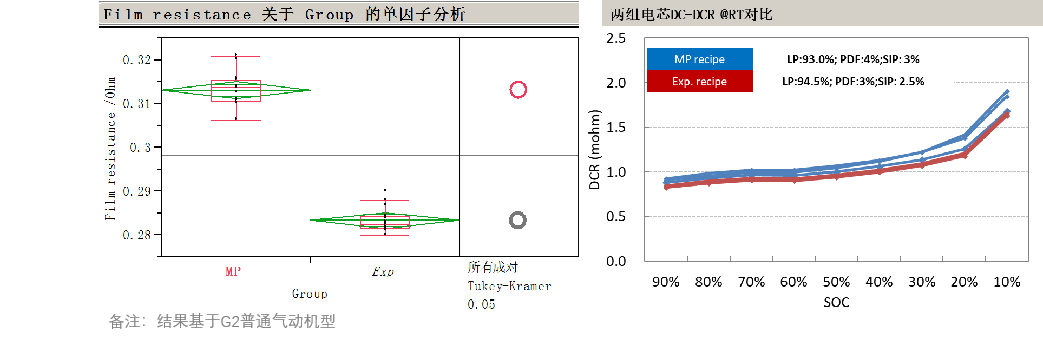

极片配方开发评估

在浆料配方开发中,引入膜片电阻参数,提前对配方的物性进行分析,能提前对电芯的性能进行预测判断,较大程度提高研发效率,降低研发成本;

The introduction of electrode resistance parameters can analyze the physical properties of the formula, which can predict and judge the performance of the cell in advance, improve efficiency and reduce cost;

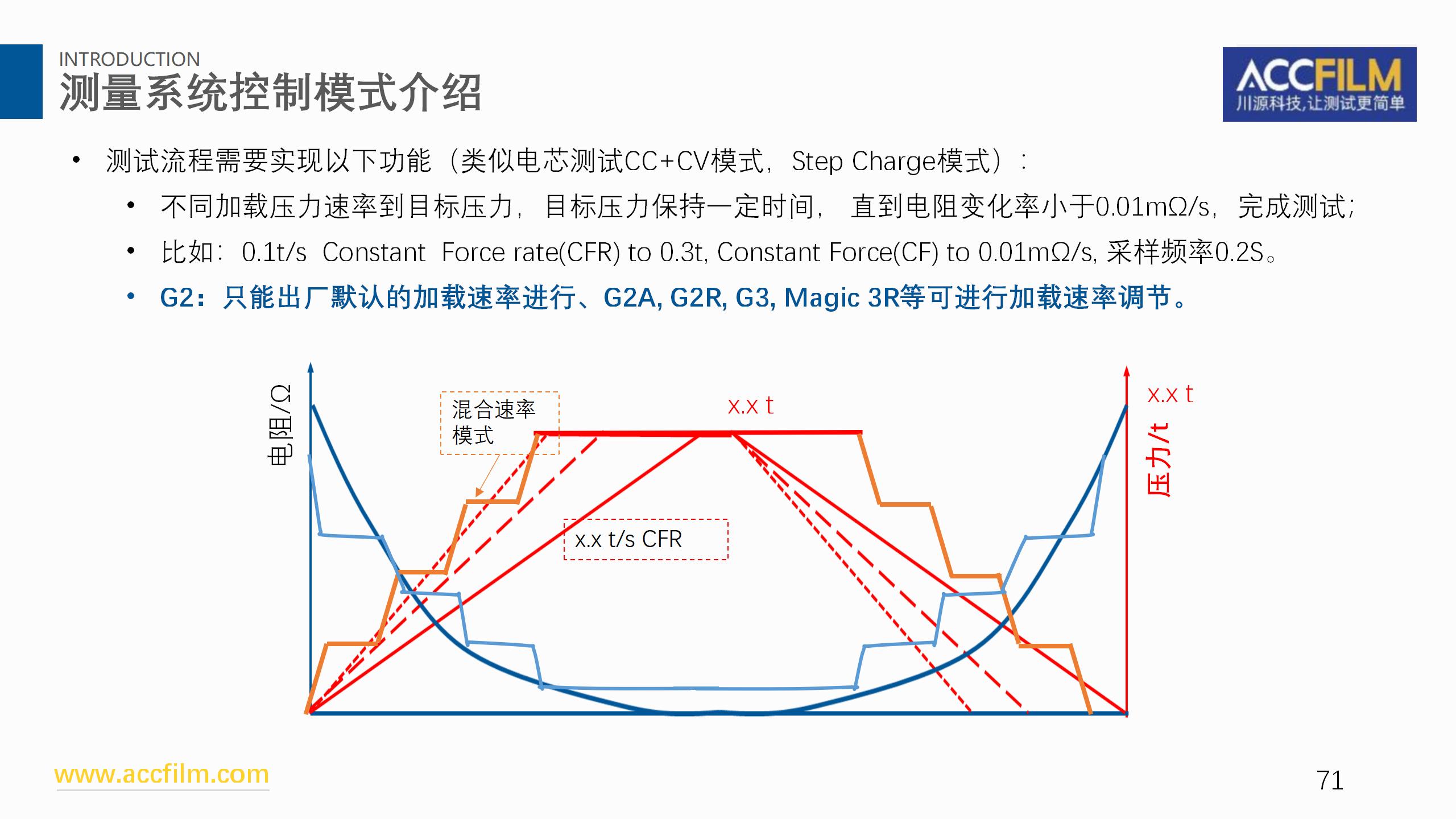

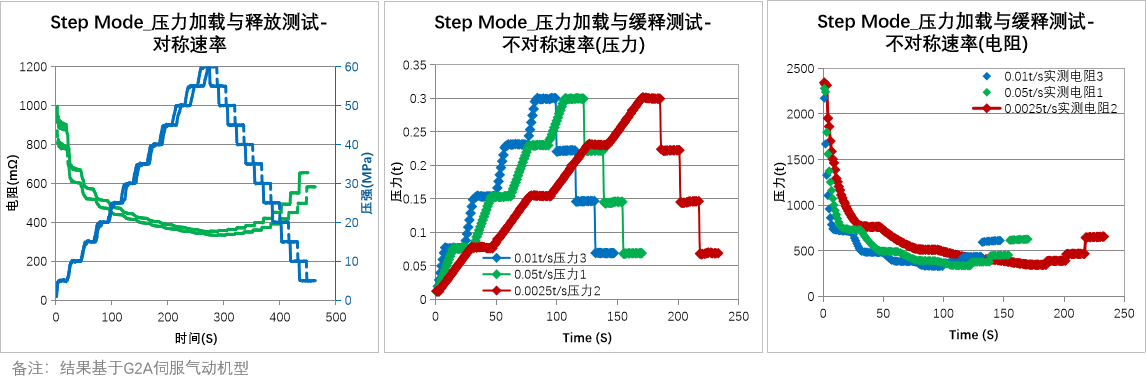

Step Mode_压力加载与缓释控制模式下极片电阻分析

基于新一代伺服控制技术,可以实现极片在不同速率+Step压力加载与释放条件下电阻及厚度等相关特性测量与评价,为极片及锂电池分析的评估提供了新的测量表征维度;

可以看出:不同极片在相同模式下反应出

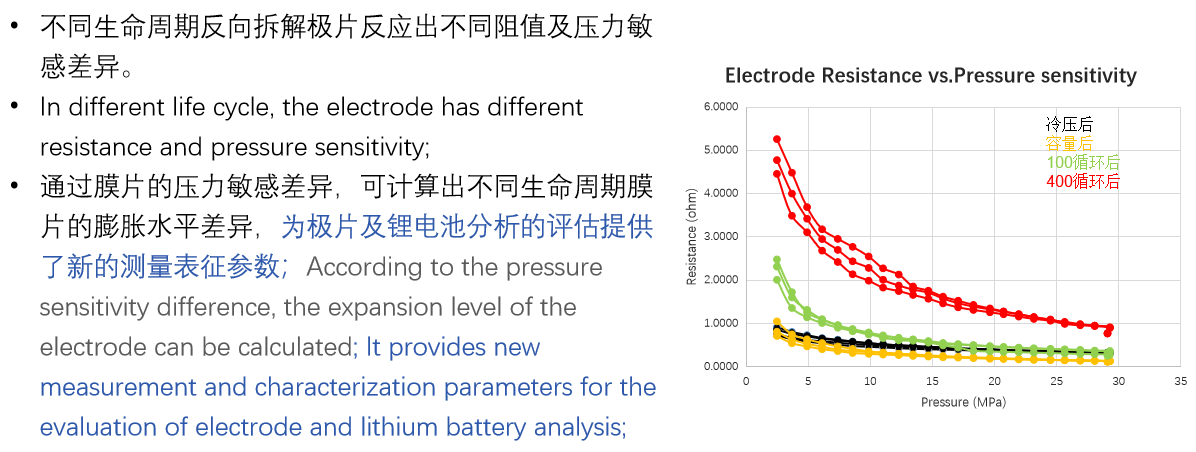

连续线性模式_不同生命周期极片评估

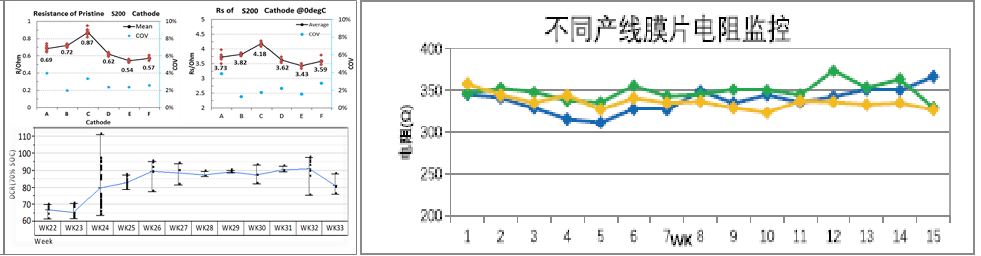

生产制程稳定性监控

当前,与电芯性能稳定性关联度最高的“膜片电阻”未进行监控;

The electrode resistance, which has the highest correlation with cell performance, is not monitored;

膜片电阻监控的导入,可降低生产风险、提高生产效率及产品可靠性;

The introduction of electrode resistance monitoring can reduce production risk, improve production efficiency and reliability;

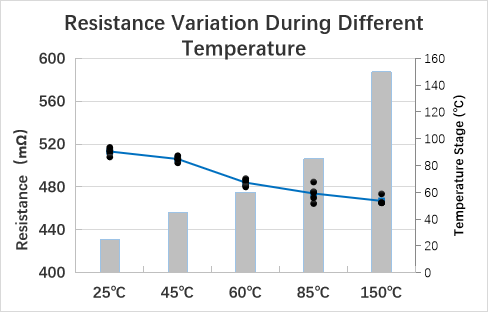

不同温度极片电阻分析

基于新一代伺服压力控制与精密循环控温技术,控温型膜片电阻测试系统可以实现不同温度下(-20~250℃)极片导电性测量与评价。Based on a new generation of servo pressure control and precision cyclic temperature control technology, the new test system can realize the measurement of the conductivity of electrode at different temperatures (-20~250 °C).

示例:在RT~150℃区间内,某正极极片的电阻随便温度平台的升高电阻阶梯下降,总下降比例约为9%。Example: From RT~150°C, the resistance of positive electrode gradually decreases at different temperature, and the overall decrease ratio is about 9%.

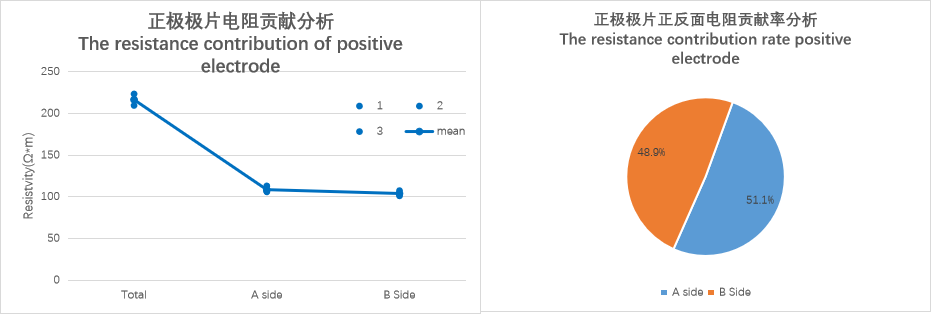

极片电阻正反面分解

基于新型多探针测量技术,新一代膜片电阻仪能实现极片整体电阻测量及其正反面电阻的分解,为产品开发及失效分析提供新的评价方法;Based on the multi-probe technology, the overall resistance, A and B sides can be tested, providing a new method for R&D and FA.

正极极片的正反面电阻基本一致,正反面电阻之和与整体电阻一致,证明测量方法的可靠性; The A and B sides of the positive electrode are basically the same, and the A and B sides are consistent with the overall resistance, which proves the reliability of the measurement method;

审核编辑 黄宇

- 相关推荐

- 电阻测试仪

-

synopsys&Mentor设计流程2022-07-08 499

-

R&S ZNLE矢量网络分析仪的主要特点及应用优势2020-12-09 1343

-

R&S FSL6台式信号分析仪的功能特点及应用范围2020-12-09 1265

-

欧拉 Summit 2021 安全&可靠性&运维专场:主流备份技术探讨2021-11-10 1774

-

485&&Modbus协议2021-11-23 525

-

存储类&作用域&生命周期&链接属性2021-12-09 590

-

如何区分Java中的&和&&2023-02-24 1498

-

if(a==1 && a==2 && a==3),为true,你敢信?2023-05-08 1079

-

HarmonyOS &润和HiSpark 实战开发,“码”上评选活动,邀您来赛!!!2022-04-11 1135

-

你使用shell脚本中的2>&1了吗?2023-07-30 1839

-

摄像机&雷达对车辆驾驶的辅助2022-11-26 865

-

高通LE Audio Qualcomm S5 & S3 Gen2 training2023-03-14 552

-

解读北美运营商,AT&T的认证分类与认证内容分享2024-06-05 527

-

FS201资料(pcb & DEMO & 原理图)2024-07-16 131

-

onsemi LV/MV MOSFET 产品介绍 & 行业应用2024-10-13 269

全部0条评论

快来发表一下你的评论吧 !